Validating the athermal contribution of electropulsing treatment utilizing T-type Mg specimen

Metal Design & Mechanics Lab (P.I.: Professor Taekyung Lee) successfully introduced a novel methodology, utilizing T-type specimen, to completely separate the thermal and athermal contributions of electropulsing treatment (EPT) within a single experiment. The key innovation was establishing two reference points (namely, points C and D) where temperatures remained comparable (<6 K deviation). Such a setup ensured that any difference in microstructural evolution arose solely from the athermal effects. The results consistently demonstrated that the region exposed to the electric current (i.e., point C) exhibited remarkably accelerated kinetics of microstructural evolution (e.g., a growth of preexisting grains, a reduction of low-angle grain boundaries, an annihilation of geometrically necessary dislcoations, and the extent of static recrystallization) compared to the heat-only counterpart (point D). This proved that the athermal EPT contribution provides an additional driving force to the strain-induced boundary migration mechanism, stimulating microstructural evolution beyond thermal effects alone. This T-type specimen offers a robust x-framework for decoupling EPT effects at the macroscale, providing a valuable tool for optimizing electrically-assisted forming and other high-efficiency manufacturing processes.

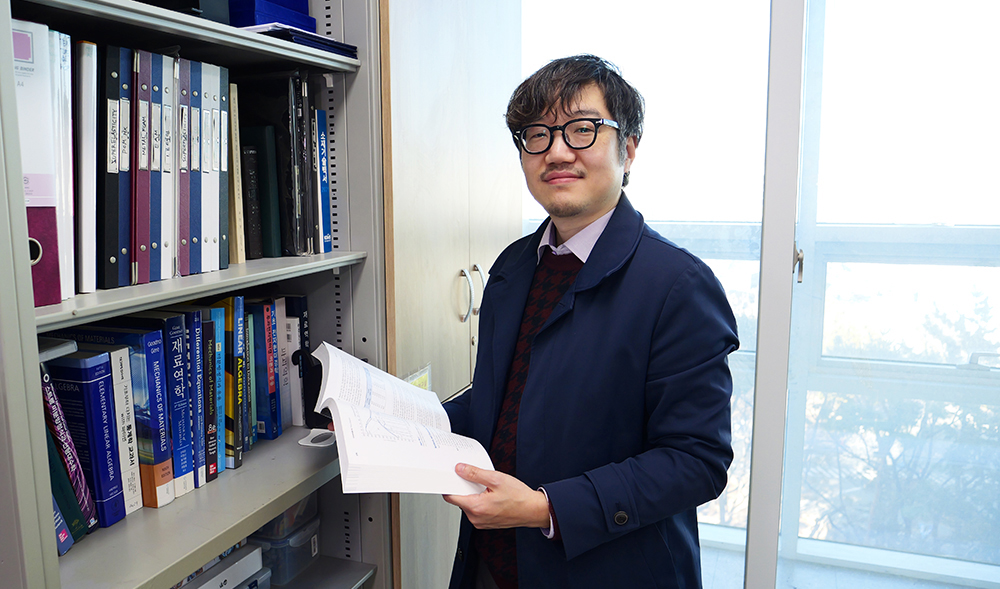

- Authors (Pusan National University): Taekyung Lee (corresponding) & Jong Han Song (1st) (School of Mechanical Engineering)

- Title of original paper: Validating the athermal contribution of electropulsing treatment utilizing T-type Mg specimen

- Journal: Journal of Magnesium and Alloys

- Web link: https://doi.org/10.1016/j.jma.2025.11.017

- Contact e-mail: taeklee@pnu.edu

953이태경교수1.jpg

(441KB)

953이태경교수1.jpg

(441KB)